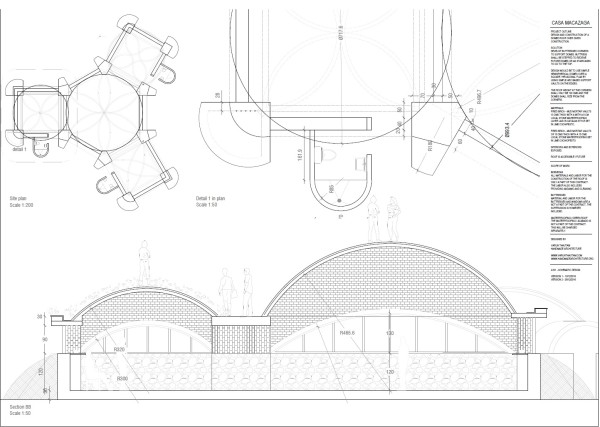

Casa Macazaga, Epitacio Huerta, Mexico

A permaculture expert as a client is bound to be an ideal one and deserves a special design. Raul Macazaga and his wife Mercedes approached me with the idea of developing a home.

A permaculture expert as a client is bound to be an ideal one and deserves a special design. Raul Macazaga and his wife Mercedes approached me with the idea of developing a home.

When I reached the site, (a large reforestation project) the foundations were already laid out on a large hexagonal plan with three square rooms by the sides. Thick Adobe walls were raized up to shoulder level. He asked me if it was possible to vault/dome the given space. I quickly realized that the space designed to be; a home was too large, the site too privileged and the client too romantic to work with.

I took measurements and went back to the drawing table, not really agreeing to the client requirement of designing a home on the given plan. Looking at the space afresh, with the symmetry and sacred geometry already in place, a monumental structure was inevitable. Space imagined was inevitably a non-territorial multi-use place rather than a home. I proposed the above plan, with the intention to create three large domes of 6mx6m buttressing a central dome of 12m laid on 6 arches. A simple idea was to use a part of a sphere and cut the sphere with the strict geometry of the hexagon/square to greate supporting arches.

Structurally, I had to stabilize the arches and the dome using the “Optimization Method” / Taught to me by Saptrem Maini at the Auroville earth Institute in 2008. The arches deviated from a catenary and the curve could not be modified, for the strictness of the geometry, however, its thickness could be varied so that the mid centre came close to a catenary. Thickness was varied with the size and type of bricks chosen.

As Epitacio Huerta received about 800 mm of rainfall in 2 months, the choice of material was Fired bricks. Adobes would not survive the variations in humidity. The challenges of waterproofing were yet to be resolved, but we went ahead with the idea of vaulting and dome building. The corners of the adobe walls were demolished to make way for stone buttresses that would receive arches. Steel windows were fabricated, that would form the centring/formwork for the arches and would stay in situ. There are no ties/members in tension and all the arches transfer the load to the ground through pure compression.

My team B fresh from their volunteering experience after building Casa Amealco, was all set to try their hand to a different type of dome. After two weeks of training on site, the team was all set to build about 220m2 of domes. Paulino Rico, Luis Enrique Menchaca, Alessandro Costa Esparza, Margarita Nava Rool, Marco Mijares started off with the corners, using a simple radius – a plastic coated steel cable fixed at the centre of the sphere.

Soon we had to switch to a steel PTR (rectangular section, with a contraption designed and fabricated by master James Anthony ) seen above. The contraption allows two axis movement and allows two bovederos (vault builders work at the same time at opposite ends).

Soon we had to switch to a steel PTR (rectangular section, with a contraption designed and fabricated by master James Anthony ) seen above. The contraption allows two axis movement and allows two bovederos (vault builders work at the same time at opposite ends).

Over two months, we successfully built the three side domes, however with several iterations of methods till we got the shape right. a lot of lessons were learned in the methods of didactics, quality control, and cost control.

We decided to follow a clay-based waterproofing initially, that did not work out. We had to redo the work again.

Several methods of waterproofing were tried here and failed miserably.

Lessons learned were as follows

- The kind of waterproofing over domes built with mud had to be flexible, as the dome was constantly expanding and contracting (like a balloon). Mud expands and contracts with the change in humidity.

- The ideal waterproofing was one that breathes, as any humidity/water entering the structure in the interior would have to escape. A sealed dome would stay wet for almost a year, as the vapor would never escape. This would make the dome humid at corners (even in the absence of rain).

- Clay as a waterproofing membrane would work perfectly only in a dry climate.

- Brick tiles work well in wet and humid climates but are initially very dry and prone to soak up a lot of water. Only after 2-3 years of exposure, are the pores filled up sufficiently to work as a waterproofing membrane. The clay tiling method (see images below) will work, only if they are protected from the rains during the first two years.

- Brick Tiles soaked in Milk will be waterproof for a few years, as the fat enters the pores and creates a seal, however, the joints between tiles will remain porous, hence reducing its ability to work in heavy torrential rainfall.

- Using alternating layers of Alum and Soap, thinly coated seals the pores of brick tiles and mortar. However, this needs to be repeated every year before the rains.

We finally decided to go with the last option of waterproofing as it is ecological and the runoff is devoid of any chemical that can contaminate the soil. All plastic membranes are known to contaminate water and the soil with microparticles.

This too proved to be a mistake, as the joints were still not impermeable. Two layers of tiles were laid with lime mortar in between them to finally seal the clay coat.

A year later, we recieved the best talent in Mexico, a combination of the legends of vault building James Anthony, Bovedas Andres Flores Castañeda along with Alfonso Luna and Margarita Nava Rool, to build the 12 m dome at the centre. Ocasionally joined by Paulino Rico.

To develop structural stability over the large laminar dome, stitching of courses was necessary to dissipate forces and carry them down to the arches in a uniform manner. James Anthony developed a design that would use overburnt bricks in the joint (of stiching) and the pattern evolved as the dome grew in size. Similar techniques are seen in the duomo of Brunelleschi, in Santa maria de Fiore (Florence).

The closing of the dome presented a unique problem, as per design, each brick had to be cut in a specific shape and presented before installing in place. The closing took a week, between the three masters. I had them reduce the thickness based on the structural calculations, to keep the center as close as possible to a catenary. Bricks were also placed as bulls towards the outside to key in the waterproofing on top, as well as to work as a stair while installing the waterproofing layer.

The project remains incomplete with an expansion of a fifth dome to complete the project. A lime-based sub flooring – Cocciopesto / Roman concrete was opted and poured into place.

A big thanks to client Raul Macazaga for this opportunity, of course, Joel Mejia for the constant work, care, and supervision!

Over the past 2 years, several visitors have come by, notably Prof Vikram Bhatt (from McGill University, Montreal), and Juan Alfonso Garduno (from Harvard University, G3 Architects, Queretaro).

[…] Nubian vaults are seldom rested upon walls. They start and end at walls. A wall is a rigid element that does not change/move. While the Nubian vault is in constant movement – breathing in and out, or growing and resting during the day. This causes the joint between the wall and the vault a challenging line to seal. It will work only in a desertic condition if a rigid waterproofing is selected. See waterproofing lessons learned in Macazaga House. […]